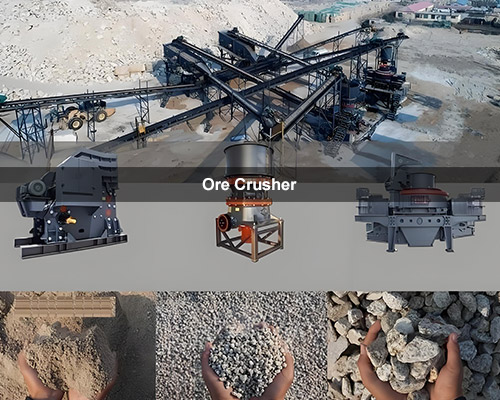

How Does an Ore Crusher Work?

Introduction to Ore Crusher

Ore crusher are essential machines in mining and mineral processing operations. They break down large rocks and ores into smaller pieces for further refinement. Crusher come in various types, including jaw crusher, cone crusher, and impact crusher, each handling materials differently.

The Crushing Process

The ore crushing process typically involves several stages:

- Primary Crushing: Large raw ore is fed into a jaw crusher or gyratory crusher, which applies compressive force to break it down.

- Secondary Crushing: Cone crusher or impact crusher further reduce the crushed material.

- Tertiary Crushing: Fine grinding may use vertical shaft impactors (VSI) or high-pressure grinding rolls.

- Screening & Classification: Vibrating screens separate particles by size.

Types of Ore Crusher

- Jaw Crusher: Use two plates (fixed and movable) to compress materials.

- Cone Crusher: Utilize a rotating mantle within a concave bowl for crushing.

- Impact Crusher: Accelerate ore against breaker plates for high-speed fragmentation.

- Hammer Mills & Roll Crusher: Used for softer ores or final size reduction.

How Crusher Improve Mineral Processing

Efficient ore crushing ensures proper liberation of valuable minerals from waste rock, optimizing downstream processes like flotation or leaching.

Choosing the Right Crusher

Selection depends on ore hardness, feed size, desired product size, and capacity requirements.

Conclusion

Understanding how ore crusher work helps mining operations optimize their processing plants. Whether using jaw, cone, or impact crusher, proper crushing ensures efficient mineral extraction.