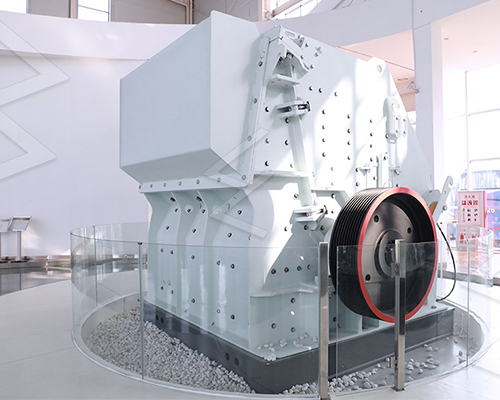

CI5X Series Impact Crusher

Product Introduction

The CI5X Series Impact Crusher, developed by Liming Heavy Industry (Henan Liming Heavy Industry Science & Technology Co., Ltd.), is a next-generation impact crushing solution designed for high-efficiency secondary and tertiary crushing. Combining robust construction, smart hydraulic adjustment, and wear-resistant materials, the CI5X crusher delivers superior performance in mining, construction, and recycling applications. It is an ideal choice for crushing medium-hard to hard materials like limestone, granite, concrete, and construction waste, ensuring optimal productivity with low energy consumption and easy maintenance.

Working Principle

The CI5X Impact Crusher operates using impact force to break down materials:

- Material Entry – The feed material enters the crushing chamber through the hopper.

- High-Speed Rotor Impact – A heavy-duty rotor with precision-balanced hitters accelerates materials toward the impact plates.

- Crushing & Rebounding – The materials are repeatedly struck and crushed between the rotor and impact aprons.

- Adjustable Discharge Size – The hydraulic adjustment system allows precise control over the output particle size.

- Final Product Discharge – Uniformly crushed materials are discharged through the adjustable discharge opening.

The fully automated hydraulic system ensures smooth operation, reducing downtime and maintenance costs.

Applications

The CI5X Impact Crusher is widely used in:

- Mining & Quarrying – Crushing hard rocks (granite, basalt, limestone) for aggregates.

- Construction Waste Recycling – Processing concrete, bricks, and demolition debris.

- Highway & Railway Construction – Producing high-quality stone aggregates for road bases.

- Cement Production – Pre-crushing clinker and raw materials before grinding.

- Sand & Gravel Production – Fine-tuning aggregate size for construction purposes.

Advantages of CI5X Impact Crusher

- High Crushing Efficiency – Innovative rotor design maximizes impact force for better crushing performance.

- Wear-Resistant Materials – High-chrome hammers and impact plates extend service life.

- Hydraulic Adjustment – Easy setting changes for different output sizes without stopping the machine.

- Low Maintenance – Simple design with accessible wear parts reduces downtime.

- Energy Saving – Optimized crushing chamber reduces power consumption while maintaining production rates.

- Smart Control System – PLC automation ensures stable operation with minimal human intervention.