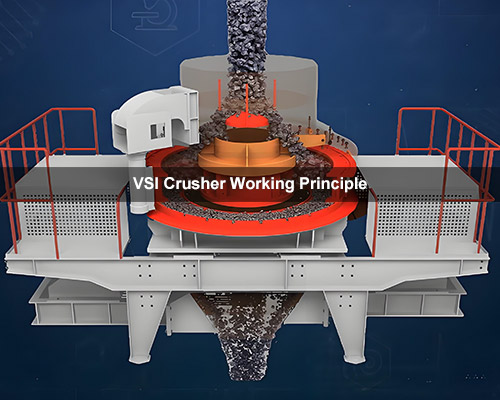

VSI Crusher Working Principle

Introduction to VSI Crusher

Vertical Shaft Impact (VSI) crusher, such as Liming Heavy Industry’s VSI6X Sand Maker, revolutionize rock-on-rock crushing technology. Designed for tertiary and quaternary applications, these machines excel in producing high-quality aggregates for construction, mining, and industrial sectors.

Core Working Mechanism

The VSI crusher operates on three fundamental principles:

- Accelerated Material Ejection: Material enters the crusher through the hopper and is accelerated by the rotating rotor (up to 70 m/s in our VSI6X model).

- Rock-on-Rock/Rock-on-Iron Crushing: Particles collide either with the anvil rings (rock-on-rock) or impact plates (rock-on-iron), depending on configuration.

- Precise Particle Shaping: Cascading material creates cubical end products ideal for concrete aggregate and engineered sand.

Key Advantages of Liming’s VSI Technology

- Energy-Efficient Design: The VSI6X series reduces power consumption by 30% compared to conventional crusher.

- Wear-Resistant Components with optimized alloy mixtures extend service intervals.

- Hydraulic Lid Opening simplifies maintenance access.

- Automated Control Systems monitor rotor balance and vibration.

Applications Across Industries

Our VSI crusher serve critical roles in:

- Manufactured sand production for concrete and asphalt

- Mineral processing (e.g., iron ore, bauxite)

- Recycling (glass, slag, construction waste)

- Road base material preparation

Comparative Advantage

Unlike traditional jaw crusher (like our C6X series) or cone crusher (such as the HPT series), VSI crusher provide superior particle shape control with lower fines generation—making them indispensable for modern aggregate specifications.

Conclusion

Liming Heavy Industry’s VSI crusher technology combines mechanical precision with operational efficiency. For operations requiring premium-shaped aggregates or specialized sands, our VSI6X series delivers proven performance. Contact our technical team to configure the ideal crushing solution for your material processing needs.