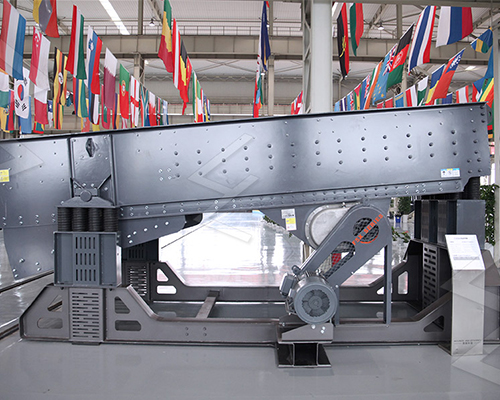

F5X Series Vibrating Feeder

Introduction to F5X Series Vibrating Feeder

The F5X Series Vibrating Feeder from Henan Liming Heavy Industry Science & Technology Co., Ltd. is engineered for extreme-duty feeding operations in mining, quarrying, and aggregate production plants. Designed to withstand heavy impact loads and large feeding capacities, this vibrating feeder excels in transferring bulky, heavy, and abrasive materials to crushers and screening systems with remarkable efficiency and durability.

Working Principle of F5X Vibrating Feeder

The F5X feeder operates on an advanced vibration mechanism featuring:

- Dual-Motor Vibratory Drive – Provides stable, powerful linear vibration for consistent material flow

- Heavy-Duty Grizzly Bars – Withstands impact from large rocks up to 1.5m in size

- Modular Pan Construction – Allows easy replacement of wear parts

- Adjustable Vibration Intensity – Enables precise control of feed rate from 150-800TPH

- Integrated Spring Suspension – Absorbs shock loads for smooth operation

The feeder’s linear vibration motion ensures steady material flow while preventing bridging or segregation, making it ideal for primary feeding stations.

Applications of F5X Vibrating Feeder

The F5X series is perfectly suited for:

- Primary Crushing Stations – Feeding large rocks to jaw/gyratory crushers

- Mining Operations – Handling ROM ore in mineral processing plants

- Aggregate Production – Feeding quarry run material to primary crushers

- Recycling Facilities – Processing demolition concrete and construction waste

- Heavy Industry – Transferring slag and other industrial byproducts

Key Advantages of F5X Feeder

- Superior Strength – Extra-thick steel plate construction withstands impacts up to 1000t capacity

- High Efficiency – Dual-motor excitation enables 30% higher throughput than conventional feeders

- Low Maintenance – Modular wear plates and accessible components reduce downtime

- Adaptability – Handles materials from fine powders to 1.5m lumps

- Smart Operation – Optional variable frequency control for precise feed rate adjustment