100 TPH Quartz Sand Production Line in Pakistan

Customer Profile

Location: Pakistan

Material: Quartz Stone

Capacity: 100 Tons Per Hour

Application: Construction Sand and Aggregate Production

Project Overview

A Pakistani construction company needed a reliable sand production line to process quartz stone into high-quality aggregates for infrastructure projects. The requirements included a stable 100TPH output with low maintenance costs and long-lasting equipment.

Challenges

- High Hardness of Quartz: Quartz is a tough material that can wear down conventional crushers rapidly.

- Stable Output Requirement: The customer needed a continuous 100TPH production with minimal downtime.

- Sand Quality Standards: The final product had to meet strict construction-grade specifications with uniform particle size.

Solution – Liming Heavy Industry Customized Quartz Crushing Line

Liming Heavy Industry provided a complete 100TPH sand production line with the following advanced equipment:

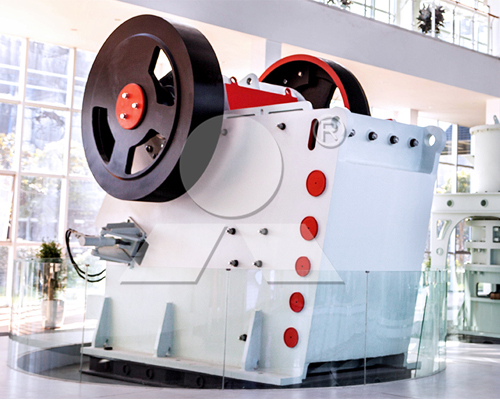

1. Primary Crushing – PE750×1060 Jaw Crusher

- Function: Coarse crushing of raw quartz into smaller pieces (150-200mm).

- Advantages: Strong structure, high capacity, and wear-resistant jaw plates for long service life.

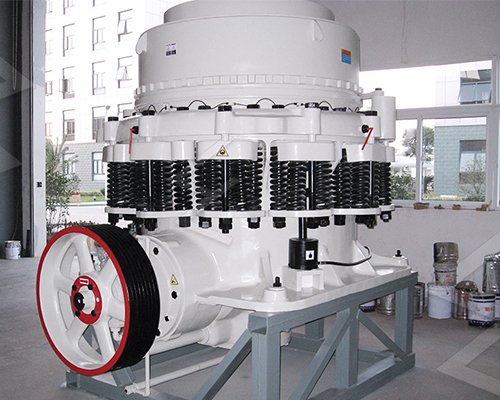

2. Secondary Crushing – HPT300 Multi-Cylinder Hydraulic Cone Crusher

- Function: Further reduces quartz to 30-50mm with high efficiency and low energy consumption.

- Advantages: Hydraulic adjustment system for stable discharge size, ideal for hard materials like quartz.

3. Tertiary Crushing & Sand Making – VSI6X1150 Sand Maker

- Function: Produces high-quality artificial sand with uniform grain shape for construction use.

- Advantages: Optimized impeller design for higher output (0-5mm sand) and lower wear.

4. Screening – 3YZS2460 Vibrating Screen

- Function: Separates aggregates into different sizes (0-5mm, 5-10mm, 10-20mm).

- Advantages: High screening efficiency, durable screen mesh for abrasive materials.

5. Auxiliary Equipment

- Belt Conveyors – Ensures smooth material transfer between machines.

- Dust Removal System – Reduces environmental pollution for eco-friendly operation.

Technical Highlights

- Energy Saving: HPT300 & VSI6X1150 reduce power consumption by 15% compared to traditional crushers.

- Durability: Tungsten carbide wear parts extend equipment lifespan in quartz crushing.

- Automation: PLC control system ensures stable operation with minimal manual intervention.

Project Results

- Output Achieved: 110-120TPH (exceeding customer expectations).

- Final Product: High-quality 0-5mm sand and 5-20mm aggregates meeting ASTM standards.

- Downtime Reduction: Smart maintenance design reduces unplanned shutdowns.

Customer Feedback

“Liming’s equipment has greatly improved our sand production efficiency. The VSI6X sand maker produces excellent quality sand, and the HPT cone crusher runs smoothly even with hard quartz. We are very satisfied with Liming’s professional support!” — Project Manager, Pakistan Construction Company