150 TPH Antimony Ore Crushing Plant in Thailand

Client Overview

Our client is a leading mining company in Thailand, specializing in antimony ore extraction and processing. Facing challenges in achieving optimal crushing efficiency and production stability, they sought a reliable solution to ensure high output with minimal downtime.

Project Overview

- Material: Antimony Ore

- Capacity: 150 tons per hour (TPH)

- Location: Thailand

- Equipment Provider: Liming Heavy Industry (LMHI)

The client required a high-capacity, durable crushing plant that could handle the hardness and abrasiveness of antimony ore, ensuring consistent 150TPH production with minimal wear and maintenance.

Challenges

- High Hardness & Abrasiveness – Antimony ore is tough, requiring robust crushing machines.

- Production Stability – Uninterrupted operation was crucial to meet hourly targets.

- Dust & Noise Control – Compliance with Thailand’s environmental regulations was essential.

- Space Constraints – The plant needed a compact yet efficient layout.

Solution by Liming Heavy Industry

Our team designed a complete crushing & screening solution, leveraging high-performance Liming crushers with wear-resistant components. The setup includes:

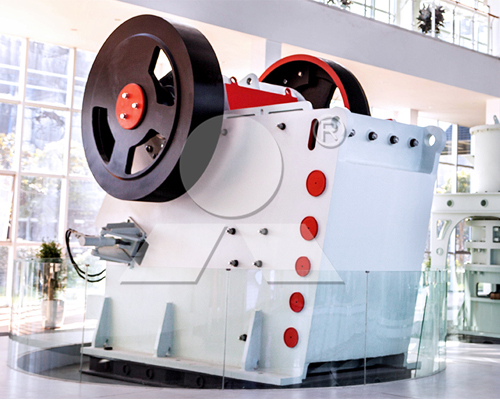

1. Primary Crushing – C6X Jaw Crusher

- Model: C6X145

- Feed Size: ≤1000mm

- Output Size: ≤250mm

- Power: 160kW

- Advantage: High crushing ratio, strong structure, and optimized kinematics for tough ores.

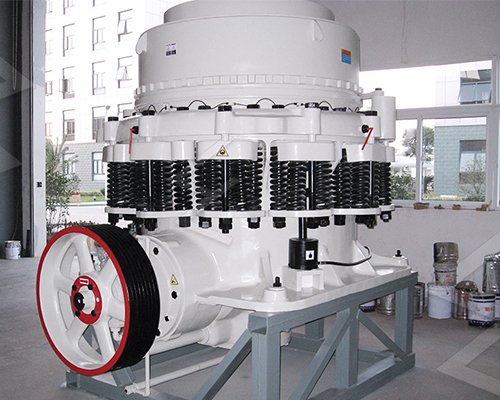

2. Secondary Crushing – HPT Multi-Cylinder Hydraulic Cone Crusher

- Model: HPT300

- Feed Size: ≤250mm

- Output Size: ≤40mm

- Power: 315kW

- Advantage: Automatic hydraulic adjustment, superior particle shape, and lower wear costs.

3. Screening – S5X Vibrating Screen

- Model: S5X2460-3

- Screen Layers: 3

- Capacity: 150-200TPH

- Advantage: High screening efficiency, durable structure, and low noise.

4. Supporting Equipment

- VU Sand Making System – For fine particle control.

- Dust Suppression System – Eco-friendly operation.

Technical Highlights

- Smart Automation – PLC control system for smooth operation.

- Wear-Resistant Materials – Extended service life under abrasive conditions.

- Modular Design – Easy installation and future scalability.

- Energy Efficiency – Optimized power consumption.

Project Results

- Achieved 150TPH output consistently without breakdowns.

- Reduced maintenance costs by 30% with durable wear parts.

- Met environmental standards with efficient dust control.

- Improved ROI due to high uptime and productivity.

Customer Feedback

“Liming Heavy Industry provided a perfect solution for our antimony ore processing. The C6X jaw crusher and HPT cone crusher deliver outstanding performance with low maintenance. The whole plant runs smoothly, exceeding our expectations.”

– Project Manager, Thailand Mining Co.