150 TPH Manganese Ore Crushing Plant In Indonesia

Client Overview

Our client is a well-established mining company operating in Indonesia with extensive experience in manganese ore extraction. Facing increasing market demand for processed manganese, they sought to upgrade their crushing capabilities to achieve higher production efficiency while maintaining product quality standards.

Project Background

The Indonesian mining company required a complete crushing solution capable of processing 150 tons of manganese ore per hour. Their existing setup couldn’t meet production targets, suffered from frequent breakdowns, and produced inconsistent particle sizes affecting downstream operations.

Key Challenges

- Material Hardness: Manganese ore’s high abrasiveness demanded durable equipment

- Throughput Requirements: Existing system couldn’t achieve 150 TPH consistently

- Particle Size Control: Needed precise output gradation for downstream processing

- Tropical Environment: Equipment needed to withstand Indonesia’s humid, corrosive conditions

- Space Limitations: Compact equipment configuration required for site constraints

Crushing Solution

Liming Heavy Industry designed a custom two-stage crushing system featuring:

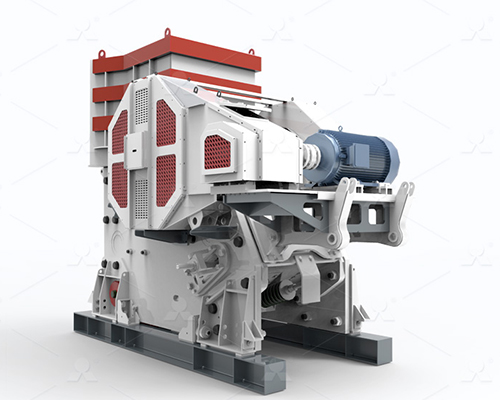

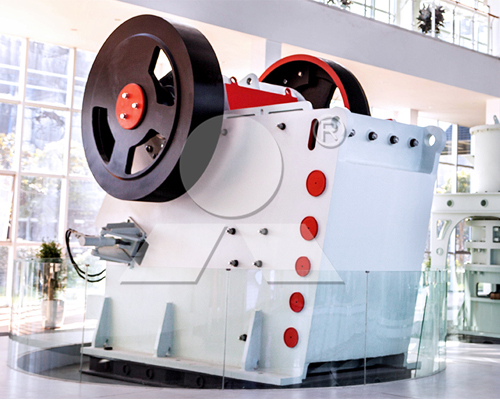

- Primary Crushing: PE900×1200 Jaw Crusher

- Capacity: 150-350TPH

- Feed opening: 900×1200mm

- Features: Deep crushing chamber, durable manganese steel jaws

- Benefits: Handles large lump sizes (≤750mm), highly efficient for primary reduction

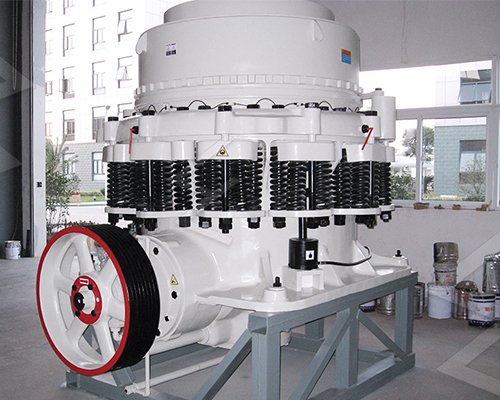

- Secondary Crushing: HPT300 Cone Crusher

- Capacity: 70-400TPH

- Features: Multi-cylinder hydraulic design, automatic control system

- Benefits: Produces uniform cubical product shape, ideal for hard ores

- Closed-side settings adjustable from 19-51mm

- Supporting Equipment

- Vibrating Feeder: ZSW490×130 to ensure consistent feed

- Vibrating Screen: 3YK2460 for precise size classification

- Belt Conveyors: Custom lengths to connect all components

Technical Highlights

- Advanced automation system monitors production parameters

- Wear-resistant materials extend component life in abrasive conditions

- Energy-efficient motors reduce operational costs

- Compact layout minimizes footprint while maintaining accessibility

- Dust suppression system meets environmental regulations

Project Results

- Achieved consistent 150 TPH production capacity (exceeding client’s target)

- Final product size met specifications at 0-30mm

- Reduced energy consumption by 18% compared to previous setup

- Maintenance downtime decreased by 35%

- System operated smoothly under full load conditions

Client Testimonial

“The Liming Heavy Industry team delivered exactly what we needed – a reliable manganese ore crushing system that hits our production targets day after day. Their PE900×1200 jaw crusher handles our toughest ore without issues, and the HPT300 cone crusher produces the perfect particle size distribution for our beneficiation process. The entire system has been running continuously with minimal maintenance since installation.”

Project Manager, Indonesian Mining Company