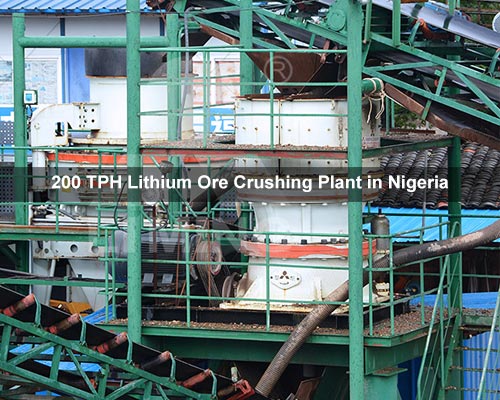

200 TPH Lithium Ore Crushing Plant in Nigeria

Client Profile

- Location: Kaduna, Nigeria

- Industry: Mining & Mineral Processing

- Material: Lithium Ore (Mohs hardness: 6-7)

- Required Capacity: 200 tons per hour

- Final Product: 0-5mm, 5-10mm, 10-20mm for further beneficiation

Project Overview

The client, a major mining company in Nigeria, needed a reliable lithium ore crushing plant to process 200 tons per hour of raw lithium ore into fine-sized aggregates for downstream processing. The challenge was to design a robust production line that could handle the hardness of lithium ore while maintaining high efficiency and minimal downtime.

Challenges

- Hard Material Properties: Lithium ore is abrasive and requires heavy-duty crushing equipment.

- High Production Demand: A stable 200TPH output was necessary with consistent particle size.

- Dust & Pollution Control: Environmental compliance was crucial for the local regulations.

- Quick Installation & Low Maintenance: The client needed minimal operational downtime.

Solution by Liming Heavy Industry

Our engineers designed a complete 200TPH lithium ore crushing and screening plant using the following high-performance equipment:

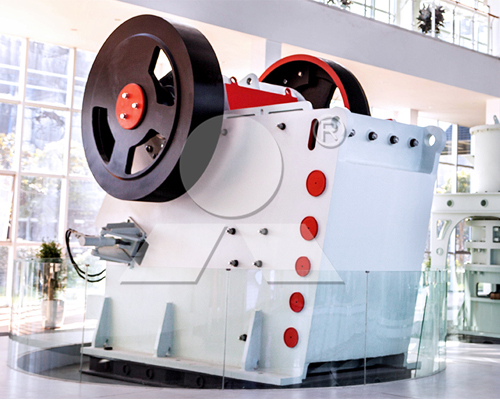

1. Primary Crushing – C6X Jaw Crusher

- Model: C6X145

- Capacity: 200-300TPH

- Input Size: ≤750mm

- Output Size: ≤200mm

- Advantages: Deep crushing cavity, high efficiency, and durability for hard rock like lithium ore.

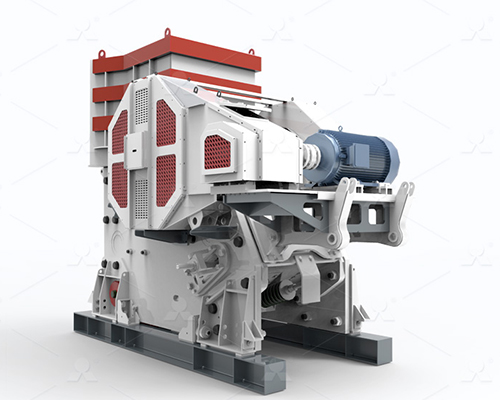

2. Secondary Crushing – HPT Multi-Cylinder Hydraulic Cone Crusher

- Model: HPT300

- Capacity: 180-250TPH

- Input Size: ≤240mm

- Output Size: ≤50mm

- Advantages: Advanced hydraulic system for fine crushing, high reduction ratio, and energy-saving design.

3. Fine Crushing & Sand Making – VSI6X Sand Maker

- Model: VSI6X1150

- Capacity: 150-200TPH

- Input Size: ≤50mm

- Output Size: 0-5mm, 5-10mm

- Advantages: High-quality sand production with excellent gradation and low wear loss.

4. Screening – S5X Vibrating Screen

- Model: S5X2460-2

- Capacity: 200-300TPH

- Screen Layers: 2-3

- Output Sizes: 0-5mm, 5-10mm, 10-20mm

- Advantages: High screening efficiency, anti-blockage design, and long service life.

5. Belt Conveyors & Dust Control System

- Closed-loop dust suppression and intelligent control system to minimize environmental impact.

Technical Highlights

- Intelligent Automation: PLC control system for real-time monitoring.

- High Wear Resistance: Crucial for lithium ore crushing with Mn steel components.

- Energy Efficiency: Optimized crushing chamber design reduces power consumption.

- Easy Maintenance: Modular structure for quick wear parts replacement.

Project Results

- Stable 200TPH Output – Consistently met production requirements.

- Excellent Particle Shape – Cubical aggregates for better beneficiation.

- Low Operational Cost – High wear resistance reduced maintenance expenses.

- Environmental Compliance – Efficient dust control meeting Nigerian standards.

Client Feedback

“Working with Liming Heavy Industry was a great experience. Their C6X Jaw Crusher and HPT Cone Crusher handled our tough lithium ore without issues. The production line runs smoothly, and the final product quality meets our needs perfectly. We highly recommend their equipment for mining projects in Africa.”

– Project Manager, Nigerian Lithium Mining Co.