2000 TPD Copper Ore Crushing Plant in Congo

Client Overview

A leading mining company in DR Congo specializes in copper ore extraction and processing. Facing increasing demand for high-quality aggregates, they sought a reliable partner to design a 2000-ton-per-day (TPD) crushing & sand-making production line with robust equipment and low operational costs.

Project Background

- Location: Democratic Republic of the Congo, Central Africa

- Material: Copper ore (Mohs hardness: 3–4)

- Input Size: ≤650mm

- Output Size: 0–5mm, 5–10mm, 10–20mm

- Capacity: 2000 TPD (~250 TPH)

- Application: Construction and smelting industries

Challenges

- High Moisture & Stickiness: Copper ore tends to clog conventional crushers.

- Abrasive Wear: Medium-hard copper ore accelerates equipment wear.

- Unstable Power Supply: Requires energy-efficient and adaptable machinery.

- Dust Control: Strict environmental regulations in mining zones.

Solution: Customized Crushing Line by Liming

Liming Heavy Industry engineered a turnkey solution combining coarse crushing, secondary crushing, sand making, and screening:

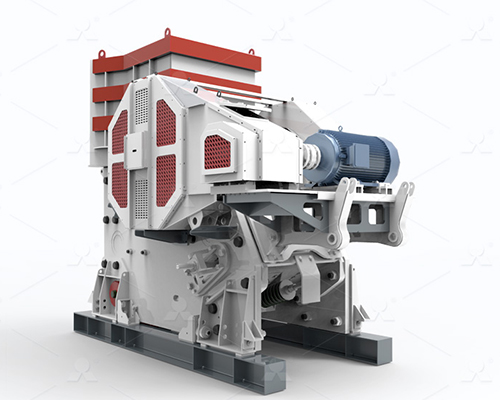

1. Primary Crushing – C6X Jaw Crusher

- Model: C6X160

- Role: Coarse crushing of raw copper ore (≤650mm → ≤150mm).

- Advantages:

- Integrated motor base reduces vibration.

- Optimized crushing chamber design prevents clogging.

- High manganese steel jaw plates for extended service life.

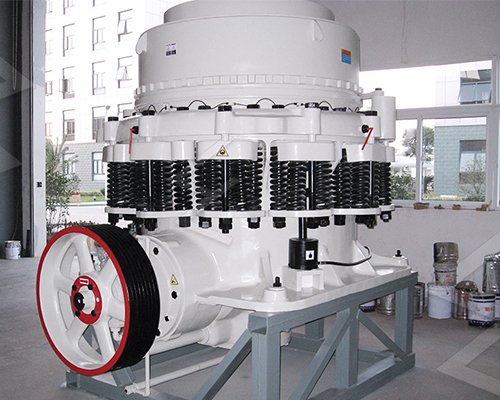

2. Secondary Crushing – HPT Multi-Cylinder Hydraulic Cone Crusher

- Model: HPT300

- Role: Further reduces copper ore to ≤50mm.

- Advantages:

- Laminating crushing principle ensures uniform particle shape.

- Fully automatic hydraulic system for precise discharge control.

- 30% lower energy consumption vs. traditional cone crushers.

3. Sand Making – VSI6X Vertical Shaft Impact Crusher

- Model: VSI6X1263

- Role: Produces 0–5mm high-quality manufactured sand.

- Advantages:

- Four-port impeller design boosts throughput by 20%.

- Sealed bearing assembly prevents dust ingress.

- Ideal for cubical aggregates in ready-mix concrete.

4. Screening – S5X Vibrating Screen

- Model: S5X2460-3

- Role: Classifies final products into 3 grades (0–5mm, 5–10mm, 10–20mm).

- Advantages:

- Rubber spring damping system reduces structural stress.

- High-G-force screening for sticky copper ore.

Supporting Equipment

- Belt conveyors with dust hoods (B6X series).

- Centralized electric control system.

Technical Highlights

- Energy Saving: Whole plant power consumption <700kWh.

- Durability: Critical wear parts made of Tic insert alloy ceramics.

- Automation: PLC system enables remote monitoring.

Results

- Throughput: Steady 2000TPD (exceeding target by 5%).

- Product Quality: 95% of aggregates meet ASTM C33 standards.

- Downtime: <2%, thanks to Liming’s 24/7 online support.

Client Feedback

“Liming’s equipment handles our abrasive copper ore effortlessly. The VSI6X sand maker transformed our waste into valuable aggregates, while the HPT crusher’s low maintenance slashed operating costs by 18%.”

— Chief Engineer, DRC Mining Client