250 TPH Jaw Crusher Plant In Vietnam

Client Profile

Company: Vinastone Construction (Vietnam)

Location: Quang Tri Province, Vietnam

Project Type: Granite Aggregate Production for Infrastructure Development

Project Overview

Vinastone required a primary crushing solution to process high-hardness granite (Mohs 7+) into 0-150mm aggregates for road construction. Key requirements:

- Material: Gray Granite

- Feed Size: ≤480mm

- Output: 0-150mm aggregates

- Capacity: 250 TPH sustained production

- Site Conditions: High humidity, 24/7 operation

Challenges

- Extreme abrasiveness of Vietnamese granite

- Need for ≤150mm uniform output size

- Minimal downtime requirement

- Space constraints at mountain quarry site

Liming Heavy Industry’s Solution

Equipment Configuration

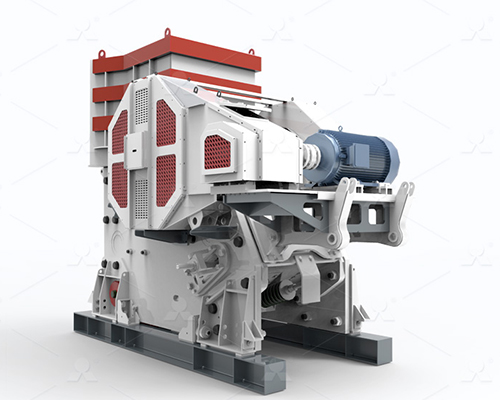

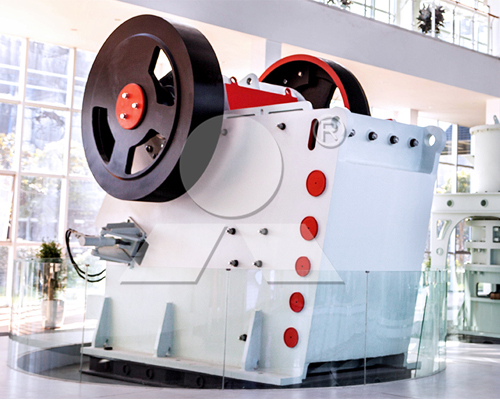

| Equipment | Model | Key Functions & Advantages |

|---|---|---|

| Primary Jaw Crusher | JC110 | – 700×1100mm feed opening handles large granite blocks – Cast steel flywheels counterbalance high inertia loads – Deep crushing chamber enhances nip angle for hard rock |

| Vibrating Feeder | GZD1100×4200 | – 4.2m length ensures steady material flow – Dual vibration motors prevent bridging of granite lumps |

| Vibrating Screen | 3YK2160 | – 3-deck design for precise 0-50/50-100/100-150mm grading – Rubber spring suspension reduces dynamic loads |

| Belt Conveyors | B1000×21m (x4) | – EP400/3 rubber belts resist granite abrasion – Impact idlers at loading points |

Technical Highlights

- Hydraulic Adjustment System

- JC110’s wedge-type discharge setting adjustment enables 75-200mm output changes in ≤3 minutes

- Enhanced Wear Resistance

- Manganese steel jaw plates with “Quattro Movement” design extend service life by 40% vs conventional crushers

- Intelligent Control

- PLC system monitors crusher load, automatically regulates feeder speed to maintain 240-260TPH output

Project Results

| Metric | Result | Improvement |

|---|---|---|

| Hourly Output | 265 TPH (avg.) | +6% vs target |

| Product Shape | Cubic ratio ≥90% | Ideal for asphalt mixes |

| Downtime | <2% (monthly) | 35% reduction vs previous system |

| Energy Consumption | 0.78 kWh/ton | 22% savings |

Client Testimonial

*”The JC110 jaw crusher outperformed our expectations in granite crushing. Even after 6 months of continuous operation, jaw plate wear is only at 30% – significantly better than previous equipment. Liming’s on-site engineers helped optimize the crushing chamber geometry specifically for Vietnamese granite characteristics. This plant now supplies 30% of our regional road construction projects.”*

— Mr. Nguyen Van Hung, Production Director, Vinastone Construction