300-400 TPH Silica Sand Processing Plant in Malaysia

Client Profile

- Location: Malaysia

- Material: Silica Sand

- Production Capacity: 300-400 tons per hour

- Application: Glass manufacturing, construction, industrial sand

Our client, a leading Malaysian construction materials supplier, needed a high-capacity silica sand processing plant to meet growing market demand.

Project Overview

The client required:

- 300-400 TPH processing capacity

- High-purity silica sand production (SiO2 > 98%)

- Multi-grade output (coarse/fine sand)

- Low iron content (Fe2O3 < 0.05%) for glass manufacturing

Challenges

- Material Characteristics – Silica sand’s extreme abrasiveness requires wear-resistant equipment

- Production Consistency – Need for stable 300-400 TPH output

- Product Purity – Strict iron content requirements for glass-grade sand

- Malaysia’s Tropical Climate – Humidity and rain impact material handling

Solution by Liming Heavy Industry

Our engineers designed a complete silica sand processing line featuring:

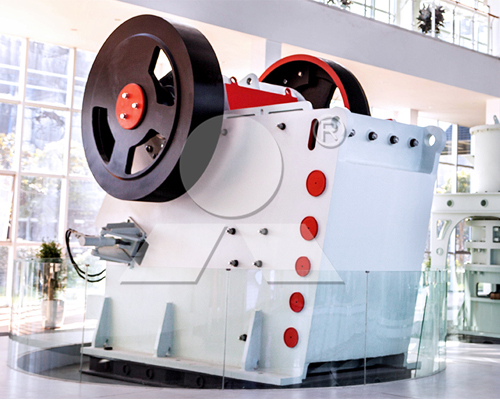

1. Primary Crushing – C6X Jaw Crusher

- Model: C6X160

- Capacity: 350-400 TPH

- Input Size: ≤850mm raw silica rock

- Output Size: ≤200mm

- Advantages:

- High manganese steel jaws withstand abrasion

- Hydraulic adjustment for quick setting changes

- 15% energy savings vs conventional jaw crushers

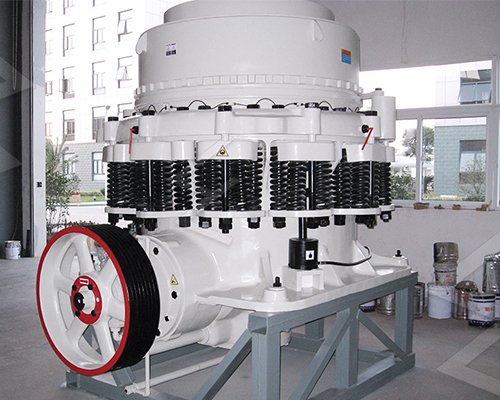

2. Secondary Crushing – HPT Multi-Cylinder Hydraulic Cone Crusher

- Model: HPT300

- Capacity: 300-350 TPH

- Input Size: ≤200mm

- Output Size: ≤40mm

- Advantages:

- Laminated crushing reduces silica sand waste

- Automatic overload protection system

- 30% longer liner life than standard cone crushers

3. Sand Making – VSI6X Vertical Shaft Impact Crusher

- Model: VSI6X1263

- Capacity: 300 TPH sand

- Input Size: ≤40mm

- Output Size: 0-5mm (adjustable)

- Advantages:

- Produces spherical sand ideal for glass manufacturing

- 60% less powder content vs conventional impact crushers

- Patented four-port rotor design extends service life

4. Supporting Equipment

- XSD Wheel Sand Washer – Removes clay and impurities

- Magnetic Separator – Reduces iron content to <0.05%

- 3YK3075 Vibrating Screen – Precise grading of sand products

Technical Highlights

- PLC Intelligent Control System – Monitors production in real-time

- High-Efficiency Cyclone Dust Collector – Meets Malaysia’s air quality standards

- Corrosion-Resistant Construction – For humid tropical conditions

- Modular Design – Quick installation and future expansion

Project Results

- 400 TPH achieved (exceeding client expectations)

- Glass-grade purity (SiO2 > 98.5%, Fe2O3 < 0.03%)

- 30% lower operating costs than conventional sand plants

- Zero wastewater discharge with closed-loop water system

Client Feedback

“Liming’s complete silica sand solution has transformed our business. The C6X, HPT and VSI6X combination delivers exceptional product quality while keeping maintenance costs low. Their local service team provides excellent support.”

Production Director, Malaysian Industrial Sands Co.