300 TPH Iron Ore Crushing Plant In Philippines

Client Profile

- Location: Philippines

- Industry: Mining & Mineral Processing

- Material: Iron Ore

- Required Capacity: 300 Tons Per Hour (TPH)

- Challenge: High abrasiveness of iron ore demanding durable equipment with high efficiency.

Project Overview

The client, a leading mining company in the Philippines, needed a 300TPH iron ore crushing plant to optimize their production efficiency. Their primary concerns included:

- Hardness & Wear: Iron ore’s abrasive nature requires robust crushing machinery.

- High Throughput: Reliable, continuous crushing with minimal downtime.

- Particle Size Control: Uniform output for downstream processing.

Liming Heavy Industry provided a complete crushing solution to meet these demands.

Challenges

- Iron Ore Hardness: High wear on crushing components.

- Production Stability: Need for 24/7 operation without breakdowns.

- Efficiency Optimization: Maximizing output while reducing energy costs.

Solution – Liming Heavy Industry’s Crushing Line

1. Primary Crushing – PE1200×1500 Jaw Crusher

- Function: Coarse crushing for large iron ore blocks (≤1000mm).

- Why Liming?

- Deep crushing chamber for higher capacity.

- High manganese steel jaw plates resist wear.

- Hydraulic adjustment for quick discharge setting changes.

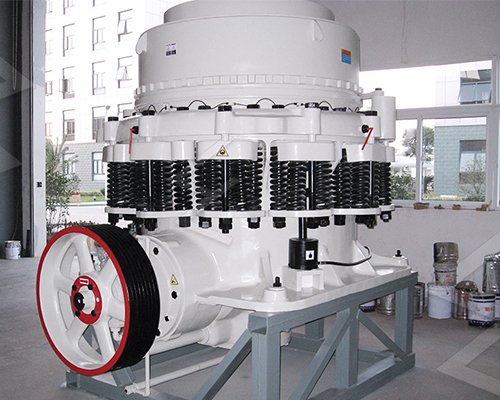

2. Secondary Crushing – HPT300 Multi-Cylinder Hydraulic Cone Crusher

- Function: Intermediate crushing to 40-70mm.

- Why Liming?

- Laminated crushing principle for better particle shape.

- Automatic hydraulic system protects against overloading.

- Longer service life with high-performance alloy liners.

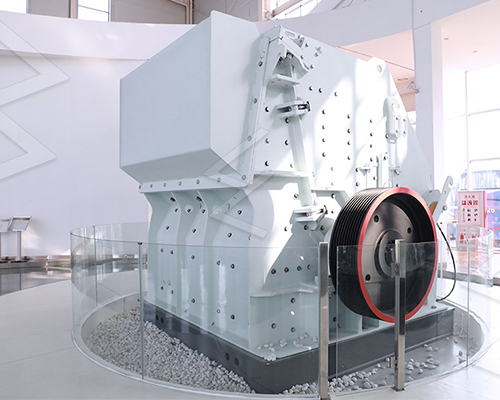

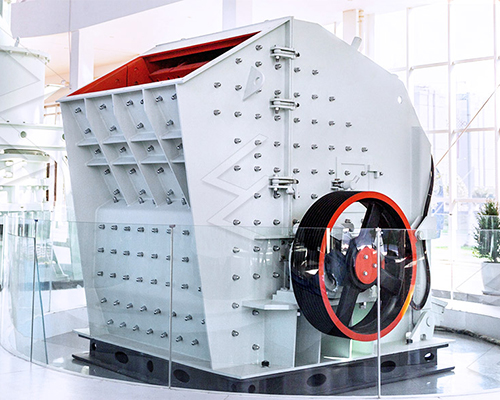

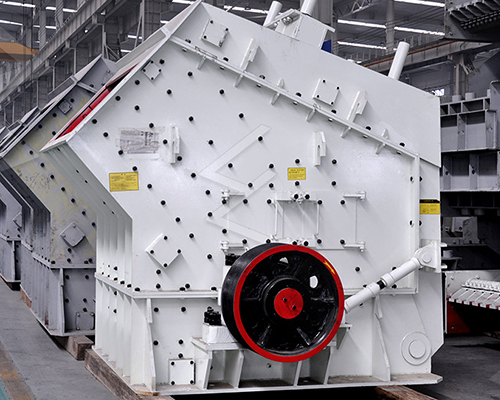

3. Tertiary Crushing – PFW1318 European Impact Crusher

- Function: Fine crushing to produce 0-20mm final product.

- Why Liming?

- Heavy-duty rotor design for high-speed impact crushing.

- Adjustable impact plates for precise product control.

- Low energy consumption with high reduction ratio.

4. Screening & Conveying – YK Series Vibrating Screen & Belt Conveyors

- Ensured accurate particle separation and smooth material flow.

Technical Highlights

- Smart Automation: PLC control system for real-time monitoring.

- Wear Resistance: Premium alloys for longer component life.

- Energy Efficiency: Optimized motor systems reduce power consumption.

Project Results

- Output Achieved: 300+ TPH consistently.

- Final Product: 0-5mm, 5-10mm, 10-20mm (adjustable).

- Downtime Reduction: <1% due to high-reliability design.

- Customer ROI: Payback within 12 months due to high efficiency and low maintenance.

Client Feedback

“Liming Heavy Industry’s crushing plant has significantly improved our iron ore processing efficiency. The PE1200×1500 jaw crusher and HPT300 cone crusher handle the tough material effortlessly, while the PFW1318 impact crusher ensures excellent final product shape. Their team delivered great technical support and training, making this a seamless project!”— Mining Operations Manager, Philippines