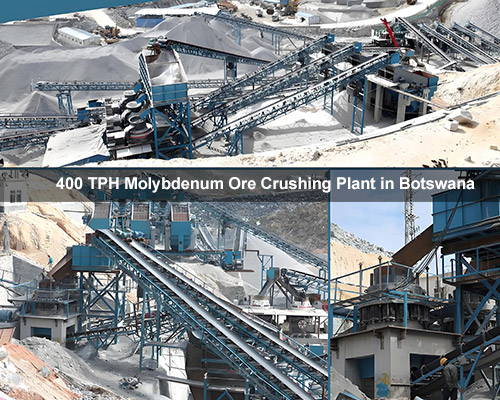

400 TPH Molybdenum Ore Crushing Plant in Botswana

Client Profile

Our client operates a mining project in Botswana, specializing in low-grade molybdenum ore extraction. Their primary challenge was achieving high-capacity crushing (400 TPH) while ensuring energy efficiency and minimal downtime.

Project Overview

The client required a complete ore processing solution capable of handling abrasive low-grade molybdenum ore with a target output of 400 tons per hour (TPH). Liming Heavy Industry engineered a customized crushing circuit combining coarse crushing, fine crushing, shaping, and screening for optimal particle size distribution.

Key Challenges

- Hard & Abrasive Ore – Low-grade molybdenum ore contains high silica content, increasing wear on crushers.

- High Capacity Demand – Requires reliable equipment for continuous 400 TPH output.

- Particle Size Control – Needed precise shaping for downstream beneficiation.

- Harsh Operating Conditions – Botswana’s dry, dusty climate demanded rugged equipment.

Crushing Solution by Liming Heavy Industry

Liming provided a complete crushing & screening plant, featuring:

1. Primary Crushing: C6X Jaw Crusher

- Role: Coarse crushing (<600mm → ≤250mm).

- Advantages: High crushing ratio, reinforced frame for heavy-duty ore, hydraulic adjustment for easy maintenance.

2. Secondary Crushing: HPT Hydraulic Cone Crusher

- Role: Fine crushing (≤250mm → ≤30mm).

- Advantages: Multi-cylinder hydraulic system for stable output, labyrinth sealing to prevent dust ingress, energy-saving design.

3. Tertiary Shaping: VSI6X Sand Maker

- Role: Further shaping (<30mm → ≤5mm cubical sand).

- Advantages: Deep rotor design for abrasive ore, low maintenance cost, high sand yield for beneficiation.

4. Screening: S5X Vibrating Screen

- Role: Accurate particle classification (5–30mm).

- Advantages: Rubber spring damping reduces vibration, modular screen panels for easy replacement.

Supporting Equipment:

- Belt Conveyors: Dust-proof design for arid climates.

- PLC Control System: Automated operation & real-time monitoring.

Technical Highlights

- Adaptive Crushing – HPT crusher’s hydraulic system adjusts to ore hardness changes.

- Wear Resistance – VSI6X uses ceramic composite wear parts (70% longer lifespan).

- Energy Savings – HPT & C6X reduce power consumption by 15% vs. conventional crushers.

Project Results

- Throughput: 410 TPH (exceeding target).

- Final Product: Uniform 0–5mm sand (ideal for leaching/pelletizing).

- Downtime: Reduced by 30% with Liming’s wear-resistant liners.

- ROI: Payback period under 18 months due to low OPEX.

Client Feedback

“Liming’s engineers tailored a solution perfectly matched to Botswana’s tough conditions. The HPT Cone Crusher handles our abrasive ore effortlessly, and the VSI6X’s sand quality improved our recovery rate. Their after-sales team provides exceptional support.”

— Mining Director, Botswana Client