600 TPH Basalt Sand Making Plant In Turkmenistan

Client Profile

Location: Turkmenistan

Industry: Construction & Mining

Material to Process: Basalt

Required Capacity: 600 tons per hour (TPH)

Project Overview

A construction company in Turkmenistan needed a large-scale sand-making production line to process basalt into high-quality artificial sand for infrastructure and building projects. They required a reliable, high-performance crushing system capable of handling 600TPH with low maintenance costs and long equipment lifespan.

Challenges

- High Production Demand – The plant required stable output to meet large-scale construction demands.

- Hard Material Processing – Basalt is highly abrasive, requiring durable crushing equipment.

- Strict Sand Gradation – The final product needed to meet construction-grade specifications.

- Limited Maintenance Support – The client wanted automatic, low-maintenance machines for remote operation.

Solution: Liming Heavy Industry’s 600TPH Basalt Sand-Making Line

After an in-depth analysis, we proposed a turnkey solution featuring Liming’s top-tier crushing and screening equipment:

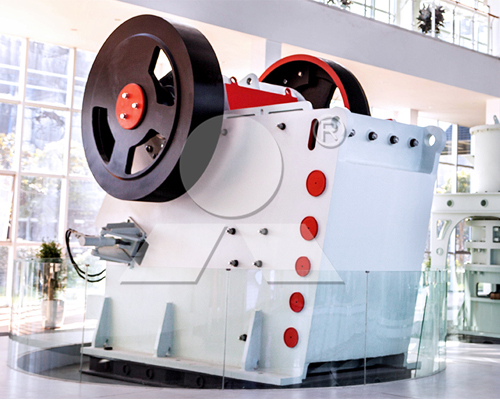

1. Primary Crushing – C6X Series Jaw Crusher (C6X160)

- Function: Coarse crushing of raw basalt into smaller chunks (≤750mm feed size).

- Advantages: High crushing ratio, robust structure, and long service life for abrasive materials.

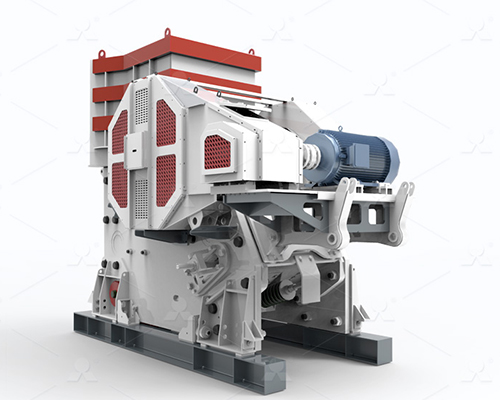

2. Secondary Crushing – HST Single Cylinder Hydraulic Cone Crusher (HST315)

- Function: Further refining basalt into medium-sized particles (≤50mm).

- Advantages: High efficiency, hydraulic adjustment, and overload protection for consistent output.

3. Tertiary Crushing & Sand Making – VSI6X Sand Maker (VSI6X1263)

- Function: Shaping basalt into high-quality artificial sand with excellent gradation (0-5mm).

- Advantages: High sand yield, low wear costs, adjustable fineness, and superior grain shape.

4. Screening & Grading – S5X Vibrating Screen (S5X3075-3T)

- Function: Classifying final sand products into different specifications.

- Advantages: Multi-deck screening, high precision, and minimal blockage.

Technical Highlights

- Automated PLC Control System – Ensures smooth operation with minimal human intervention.

- Dust Suppression & Noise Reduction – Eco-friendly design complies with environmental standards.

- Modular Design – Easy installation and maintenance in remote locations.

- High Wear Resistance – Core components use imported alloys for longer lifespan.

Project Results

- Stable 600TPH Output – The plant consistently met production targets.

- High-Quality Artificial Sand – Uniform grain shape achieved, ideal for construction.

- Low Operating Costs – Minimal downtime and reduced wear part replacements.

- Quick ROI – The client recovered investment within the expected time frame.

Client Feedback

“Liming Heavy Industry provided us with a powerful sand production plant that handles basalt efficiently. The VSI6X sand maker produces excellent sand quality, and the whole system runs smoothly with low maintenance. Their team also offered professional after-sales support, ensuring minimal downtime. We highly recommend Liming for large-scale sand-making projects!”