Kenya 100TPH Limestone Crushing Project

Client Overview

A leading construction company in Kenya sought a reliable crushing solution for its limestone quarry. The client required a high-efficiency crushing plant with an output of 100 tons per hour (TPH) to supply high-quality aggregates for local infrastructure projects.

Project Background

The client needed a complete limestone processing line to produce uniformly sized aggregates for concrete and road construction. Challenges included:

- Processing abrasive limestone with minimal wear on equipment

- Ensuring consistent 100TPH output for uninterrupted production

- Reducing operational costs while maintaining high efficiency

Challenges

- Hard & Abrasive Material: Limestone’s abrasiveness demanded wear-resistant machinery.

- High Throughput Requirement: Sustaining 100TPH without bottlenecks.

- Dust & Noise Control: Compliance with Kenya’s environmental regulations.

Solution: Liming Heavy Industry’s Customized Crushing Line

Our engineers designed a turnkey solution combining:

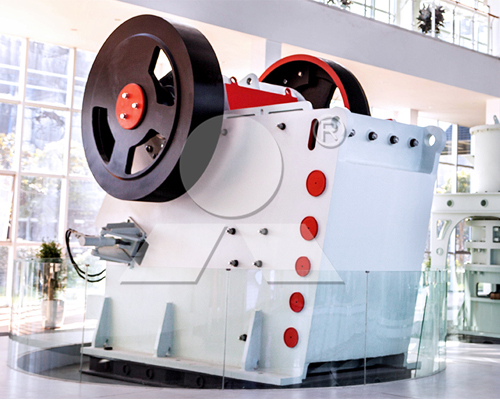

- Primary Crushing – C6X Jaw Crusher

- Model: C6X145

- Role: Coarse crushing of large limestone blocks (≤800mm).

- Advantages: Deep crushing cavity, high efficiency, and low wear costs.

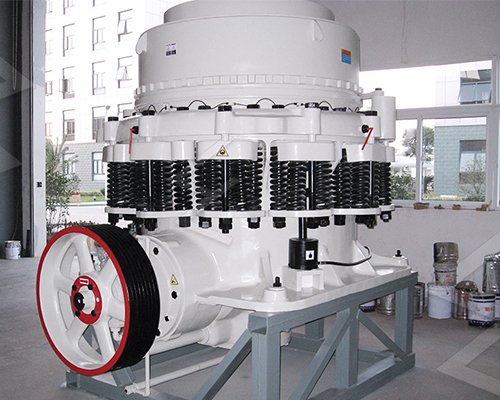

- Secondary Crushing – HPT Hydraulic Cone Crusher

- Model: HPT300

- Role: Fine crushing to produce 20–50mm aggregates.

- Advantages: Multi-cylinder hydraulic system for precise discharge adjustment.

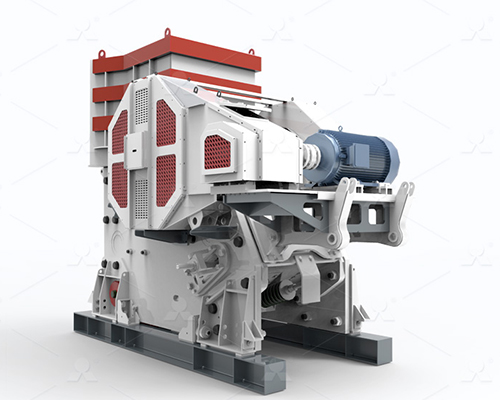

- Screening – S5X Vibrating Screen

- Model: S5X2460-2

- Role: Sieving crushed limestone into multiple grades.

- Advantages: High durability and low maintenance.

- Dust Control System

- Pulse dust collectors and water spray nozzles minimized airborne particles.

Technical Highlights

- Automated Control System: Real-time monitoring for optimal performance.

- Energy Efficiency: HPT crusher reduced power consumption by 15% vs. conventional models.

- Easy Maintenance: Quick-wear part replacement designs minimized downtime.

Results

- Production Capacity: Steady 100TPH output, exceeding client expectations.

- Product Quality: Well-graded 0–5mm, 5–20mm, and 20–50mm aggregates.

- Operational Cost: Reduced by 20% due to low wear rates and energy savings.

Client Feedback

“Liming’s equipment delivered unmatched reliability. The C6X jaw crusher and HPT cone crusher handled our tough limestone effortlessly, and the 100TPH target was consistently met. Their after-sales team provided excellent support.”