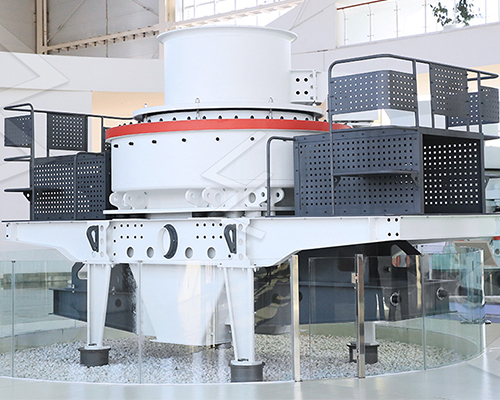

VSI5X Vertical Shaft Impact Crusher

Product Introduction

The VSI5X Vertical Shaft Impact Crusher is a high-performance crushing machine developed by Liming Heavy Industry, designed for high-quality sand production and fine crushing. Integrating German technology and innovative design, it excels in producing cubical-shaped aggregates for construction, mining, and infrastructure projects.

With its optimized rotor structure, hydraulic opening system, and wear-resistant materials, the VSI5X Crusher ensures high productivity, low maintenance, and long service life, making it a preferred choice for artificial sand making and mineral processing.

Working Principle

The VSI5X crusher utilizes a rock-on-rock or rock-on-iron crushing mechanism where raw materials are fed centrally or via cascading impact into the high-speed rotating rotor. The materials are then accelerated and thrown against the surrounding anvil ring or crushing chamber, resulting in high-energy impact crushing.

- Adjustable Particle Size: The final product size can be fine-tuned by adjusting the rotor speed and screen configurations.

- Hydraulic Lid Opening: Simplifies maintenance and wear parts replacement.

- Dual Oil Pump & Automatic Lubrication: Ensures continuous operation with minimal downtime.

Application Range

- The VSI5X Vertical Shaft Impact Crusher is widely used in:

- Artificial Sand Production (Manufactured sand for concrete, asphalt, and mortar)

- Metal & Non-Metal Mining (Crushing ores and minerals for refining)

- Highway & Railway Construction (Producing high-quality aggregates for roadbeds)

- Dam & Hydropower Projects (Providing fine aggregates for concrete)

- Recycling & Waste Processing (Crushing construction waste into reusable materials)

Key Advantages

- High Crushing Efficiency: Produces better-shaped aggregates with a cubical output for stronger concrete structures.

- Low Wear Cost: Features wear-resistant tungsten carbide and high-chromium alloy parts for extended service life.

- Hydraulic & Automatic Control: Reduces manual intervention, improving safety and efficiency.

- Energy-Saving Design: Minimizes power consumption while maintaining high throughput.

- Versatile Configuration: Supports central feeding & waterfall feeding for various material types.