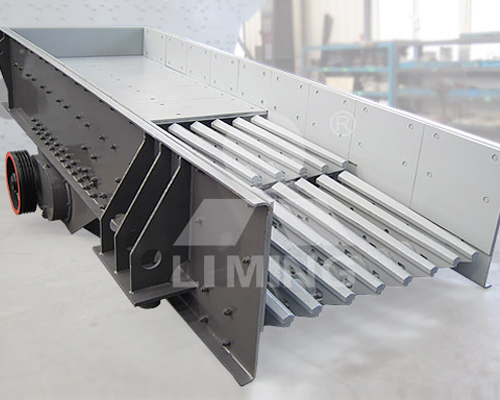

TSW Series Vibrating Feeder

Product Introduction

The TSW Series Vibrating Feeder, developed by Henan Liming Heavy Industry Science & Technology Co., Ltd., is a high-capacity, heavy-duty feeding machine designed for continuous and uniform material supply in mining, quarrying, and aggregate processing applications. With its robust construction and reliable performance, the TSW feeder ensures efficient material transfer to primary crushing equipment, maximizing productivity in demanding environments.

Equipped with an advanced exciter system, the TSW Series is ideal for handling bulky, heavy, and abrasive materials such as iron ore, granite, basalt, and construction waste. Its high-strength steel construction and wear-resistant liners make it suitable for the most challenging applications, delivering feed capacities up to 1,000 TPH.

Working Principle

The TSW Vibrating Feeder operates through an efficient vibrating mechanism, powered by:Dual-Shaft Exciter System – Generates powerful linear vibrations for smooth material flow

Heavy-Duty Grizzly Bars – Pre-screens fine materials and prevents blockages

Rubber Spring Suspension – Absorbs shock and reduces vibration transmission to the foundation

Adjustable Amplitude & Frequency – Allows precise control of feed rate

The feeder’s linear vibration motion ensures consistent material discharge, preventing segregation and optimizing crusher performance.

Key Applications

The TSW Series Feeder is widely used in:

- Mining & Quarrying – Feeding large rocks to jaw/gyratory crushers

- Aggregate Production – Handling sand, gravel, and crushed stone

- Cement & Construction – Transporting cement clinker, limestone, and other raw materials

- Recycling & Waste Processing – Feeding demolition waste and concrete debris

- Industrial Processing – Handling slag, coal, and other abrasive materials

Advantages & Benefits

- High Efficiency – Powerful exciter ensures stable and uniform feeding

- Durable Construction – Reinforced steel frame and wear-resistant liners extend service life

- Easy Maintenance – Modular design simplifies component replacement

- Customizable Options – Available with pre-screening grizzly bars for material separation

- Energy Saving – Optimized vibration mechanism reduces power consumption

- Versatile – Handles materials from fine powders to large lumps (up to 1,500mm)