100 TPH River Stone Sand Making Plant in Nepal

Client Overview

- Location: Nepal

- Material: River Stone

- Capacity Requirement: 100 TPH

- End Product: 0-5mm (40%) | 5-15mm (30%) | 15-25mm (30%)

Our client in Nepal owns a large river stone quarry and aimed to produce premium-quality sand and aggregates for local infrastructure projects. Due to the hardness and abrasiveness of river stone, they needed a robust and efficient crushing solution.

Project Challenges

- High Wear & Tear: River stone is abrasive and requires durable crushing equipment.

- Demand for Cubic Particle Shapes: The local market prefers cubical aggregate for concrete production.

- Limited Space & High Efficiency Needs: The plant required compact yet high-capacity machinery.

Solution – Customized 100 TPH River Stone Crushing Line

To address the client’s needs, Liming Heavy Industry proposed a complete sand-making plant with the following equipment:

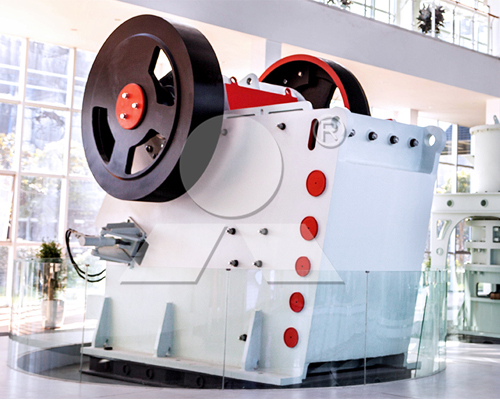

1. Primary Crushing – PE600×900 Jaw Crusher

- Function: Coarse crushing of river stone into 150–200mm sizes.

- Advantages: Strong structure, high efficiency, and low maintenance costs.

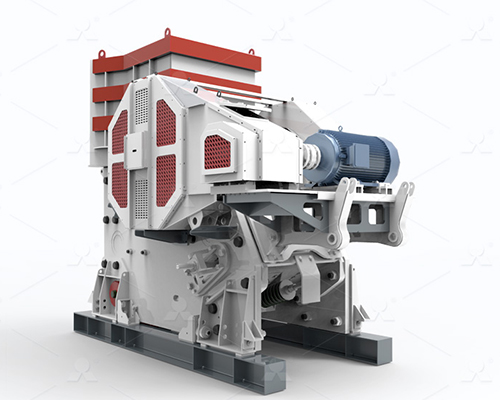

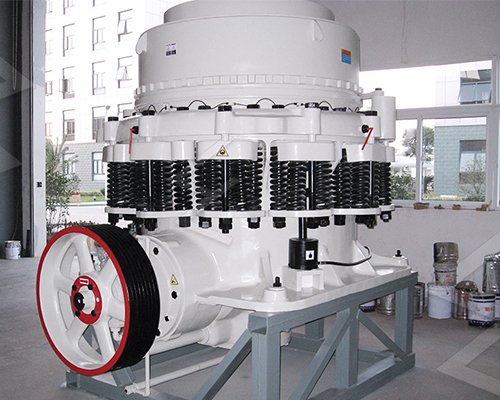

2. Secondary Crushing – HPT300 Hydraulic Cone Crusher

- Function: Further reduces the material to 30–50mm.

- Advantages: Multi-cylinder hydraulic system ensures stable output and excellent particle shape.

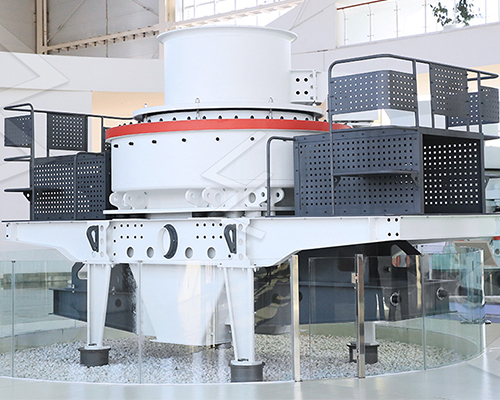

3. Sand Making – VSI6X1150 Impact Crusher

- Function: Produces high-quality sand (0–5mm) with excellent gradation.

- Advantages: Advanced rotor design minimizes wear and improves sand yield.

4. Auxiliary Equipment

- Vibrating Feeder (GZD960×3800): Ensures smooth material feeding.

- 3YK2160 Vibrating Screen: Separates materials into different sizes efficiently.

- Sand Washer (XSD3016): Cleans sand for better quality.

Customized Design Highlights

- Durability: High-chrome wear parts extend equipment lifespan.

- Intelligent Control: Automated system optimizes production efficiency.

- Environmental Protection: Dust suppression and low-noise design meet local regulations.

Project Results

- Efficient Output: Achieved stable 100 TPH production capacity.

- Superior Product Shape: Cubic aggregates improve concrete strength.

- Low Maintenance Cost: Durable wear parts reduce operational expenses.

- Full Process Support: Liming’s engineers provided installation & training.

Client Feedback

“Liming Heavy Industry’s sand-making line exceeded our expectations. The machines are highly efficient, wear-resistant, and produce perfectly shaped sand. Their after-sales service is also very responsive, ensuring smooth operation.”

— Mr. Rajesh Thapa, Project Director