200-250 TPH Granite Crushing Plant in Sri Lanka

Client Overview

Our client, a leading construction and mining company in Sri Lanka, required a high-capacity granite crushing plant to produce high-quality aggregates for infrastructure projects. They needed a reliable, efficient, and durable crushing solution to meet their production target of 200-250 tons per hour.

Project Overview

- Location: Sri Lanka, South Asia

- Material: Hard granite (compressive strength: 150-200 MPa)

- Required Output: 200-250 TPH

- Final Products: 0-5mm sand, 5-10mm, 10-20mm, and 20-30mm aggregates for construction and road paving.

Challenges:

- High Hardness of Granite – Requires durable and wear-resistant crushing equipment.

- Large Production Capacity – Needed 200-250tph output for continuous operations.

- Strict Granularity Requirements – Final products needed to meet size standards for construction.

- Limited Site Space & Environmental Regulations – Required compact, eco-friendly equipment with low dust and noise.

Liming Heavy Industry’s Solution

Our engineers designed a granite crushing plant using Liming’s high-performance crushing and screening equipment to ensure stable operation, high efficiency, and long service life.

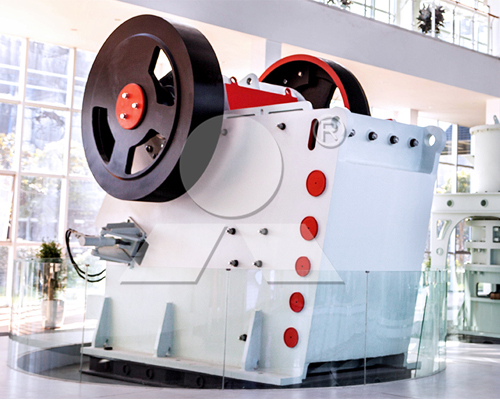

1. Primary Crushing – C6X Jaw Crusher

- Model: C6X Series Jaw Crusher

- Feed Size: ≤950mm

- Capacity: 200-250tph

- Role: High-efficiency primary crushing of large granite blocks.

- Advantages:

- Deep crushing cavity for higher output.

- Durable wear-resistant components for long service life.

- Hydraulic adjustment for quick setting changes.

2. Secondary Crushing – HPT Hydraulic Cone Crusher

- Model: HPT300

- Feed Size: ≤315mm

- Capacity: 200-250tph

- Role: Fine crushing for better particle shape and high yield.

- Advantages:

- Multi-cylinder hydraulic system for precise control.

- High crushing efficiency and low operating costs.

- Excellent particle shape for high-quality aggregates.

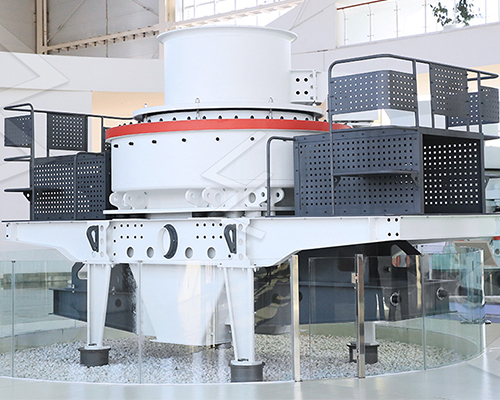

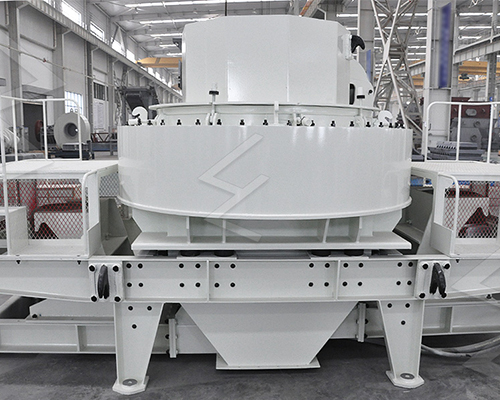

3. Tertiary Crushing & Sand Making – VSI6X Sand Making Machine

- Model: VSI6X1150

- Feed Size: ≤55mm

- Capacity: 150-200tph

- Role: Produces high-quality manufactured sand for construction.

- Advantages:

- Deep rotor design for higher sand yield.

- Low energy consumption and long lifespan.

- Adjustable gradation for different sand specifications.

4. Screening – S5X Vibrating Screen

- Model: S5X2460-3

- Screening Layers: 3

- Capacity: 200-300tph

- Role: Efficient sorting of crushed granite into different sizes.

- Advantages:

- Robust structure with high screening efficiency.

- Adjustable amplitude for precise grading.

Dust Control – Environmental Protection System

- Pulse Dust Collector & Water Spray System

- Ensured low noise and minimal dust emission, complying with Sri Lanka’s environmental standards.

Technical Highlights

- Optimized Crushing Circuit – Combined C6X Jaw Crusher + HPT Cone Crusher + VSI6X for high efficiency.

- Adjustable Output Sizes – Final products (0-5mm, 5-10mm, 10-20mm, 20-30mm) meet construction standards.

- Energy Efficiency & Reliability – Advanced hydraulic systems reduce power consumption and maintenance costs.

- Eco-Friendly Operation – Dust suppression and noise reduction features for sustainable production.

Project Results

- Production Capacity: Achieved 220-250tph, exceeding client expectations.

- Aggregate Quality: Precise shaping & grading for various construction applications.

- Operation Stability: Low downtime due to durable equipment design.

- Cost Savings: Reduced wear part replacement costs and energy consumption.

Client Feedback

“Liming Heavy Industry’s granite crushing plant has been operating smoothly since installation. The C6X jaw crusher and HPT cone crusher efficiently handle the hard granite, while the VSI6X sand maker produces high-quality sand for our concrete projects. The system is reliable, low-maintenance, and perfectly suited for our operations in Sri Lanka.”

— Operations Manager, Sri Lanka Client