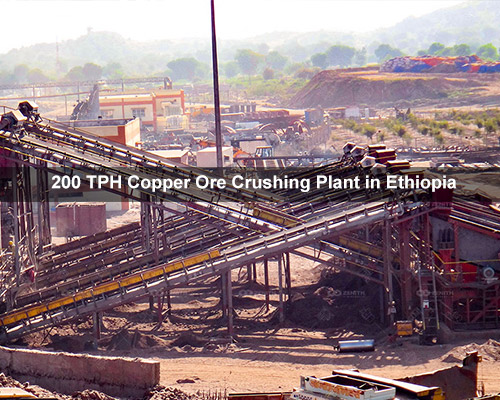

200 TPH Copper Ore Crushing Plant in Ethiopia

Client Overview

Our client is a leading mining company in Ethiopia specializing in copper ore extraction. They required a high-capacity crushing plant to process 200 tons of copper ore per hour with reliable performance and low maintenance costs.

Project Overview

- Location: Ethiopia

- Material: Copper ore

- Output Size: 0-20mm, 20-40mm

- Capacity: 200 tons per hour

Challenges

- Hard & Abrasive Copper Ore – The ore was highly abrasive, requiring durable wear-resistant crushers.

- High Throughput Demand – Needed consistent 200tph output without frequent breakdowns.

- Limited On-Site Maintenance – Required low-maintenance, user-friendly equipment.

- Environmental Compliance – Needed dust control and energy-efficient machines.

Solution: Customized Crushing Plant by Liming Heavy Industry

Equipment Configuration & Advantages

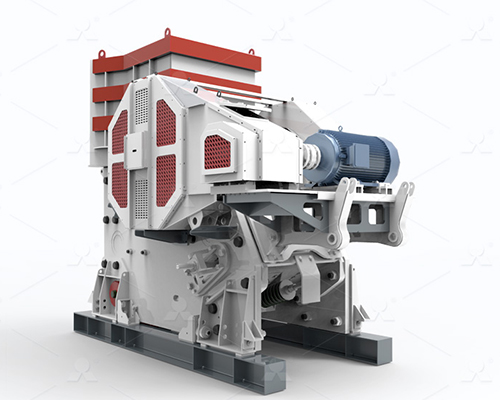

- PEW1100 Jaw Crusher (Primary Crushing)

- Function: Coarse crushing of large copper ore blocks.

- Advantages: High strength, deep crushing chamber, optimized for hard ores.

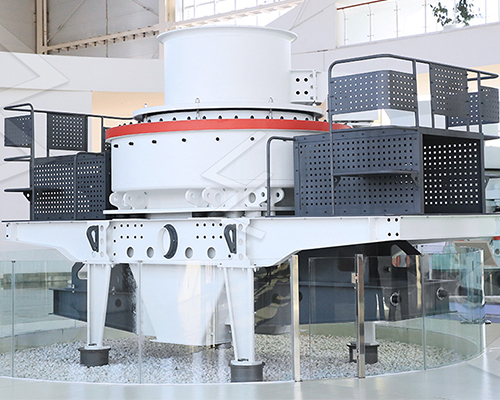

- HPT300 Multi-Cylinder Hydraulic Cone Crusher (Secondary Crushing)

- Function: Further reduces ore into finer sizes.

- Advantages: High crushing efficiency, automatic overload protection, low wear cost.

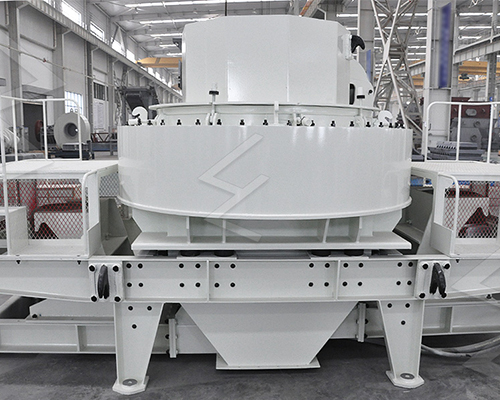

- VSI6X1263 Sand Making Machine (Tertiary Crushing & Shaping – Optional for finer output)

- Function: Shapes final product for better quality.

- Advantages: High cubical output, low noise, and dust emission.

- 3YK3072 Vibrating Screen (Screening & Grading)

- Function: Separates crushed copper ore into different sizes.

- Advantages: Multi-layer screening, high efficiency, and long service life.

- Belt Conveyor System

- Ensures smooth material transfer between stages.

Technical Highlights

- Automated Control System – Minimizes human intervention, enhances efficiency.

- Energy-Efficient Motors – Reduces power consumption and operating costs.

- Dust Suppression System – Complies with environmental regulations.

- Hydraulic Adjustment – Enables quick product size changes without downtime.

Project Results

- Stable Output: Achieved stable 200tph production as required.

- Low Downtime: Advanced wear parts reduced maintenance frequency.

- High Profitability: High-quality final product improved mine revenue.

- Long-Term Partnership: Client ordered additional equipment for future expansions.

Customer Feedback

“Liming Heavy Industry provided a complete copper ore crushing solution that exceeded our expectations. The PEW1100 jaw crusher and HPT300 cone crusher are highly efficient and durable, ensuring smooth operation. We highly recommend their machines for African mining projects.” – Mining Manager, Ethiopia