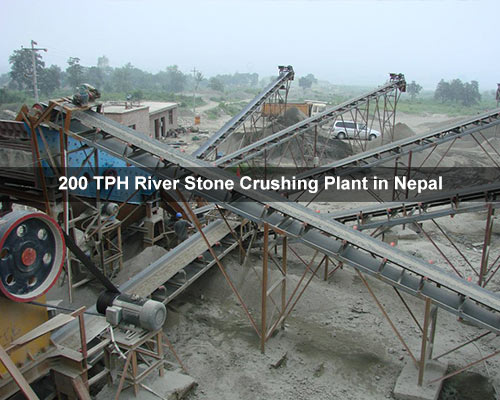

200 TPH River Stone Crushing Plant in Nepal

Client Background

Our client, a leading construction and mining company in Nepal, specializes in high-quality aggregates production. With increasing infrastructure and road construction projects, they needed a reliable crushing plant to process river stone into various sizes of sand and gravel for concrete and asphalt.

Project Overview

- Location: Nepal

- Material: River stone (hardness ~150-200MPa)

- Required Output: 200 tons per hour (TPH)

- Final Products:

- 0-5mm (sand for concrete)

- 5-20mm (aggregate for road base)

- 20-40mm (larger gravel for construction)

Key Challenges

- High abrasiveness of river stone affecting equipment durability.

- Need for precise particle shape for high-grade concrete production.

- Space constraints at the quarry site.

- Low power supply stability in remote regions.

Solution by Liming Heavy Industry

To meet the client’s requirements, Liming Heavy Industry designed a 200TPH river stone crushing and screening plant with the following configuration:

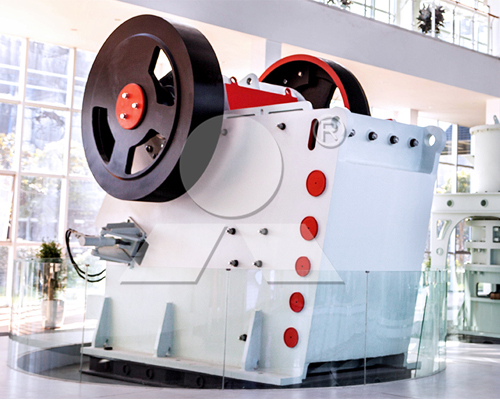

1. Primary Crushing – PE900x1200 Jaw Crusher

- Role: Coarse crushing of large river stones (≤700mm).

- Advantages:

- Deep crushing cavity for higher capacity.

- High wear resistance with Mn18Cr2 jaw plates.

- Stable and energy-efficient operation.

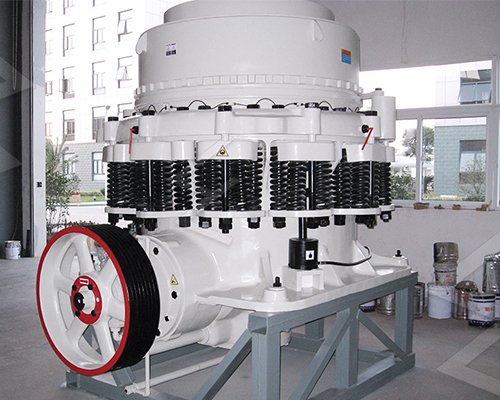

2. Secondary Crushing – HPT300 Hydraulic Cone Crusher

- Role: Intermediate crushing to produce well-shaped 5-40mm aggregates.

- Advantages:

- Multi-cylinder hydraulic system for fine particle adjustment.

- Laminated crushing principle for better particle shape.

- Low dust and low maintenance structure.

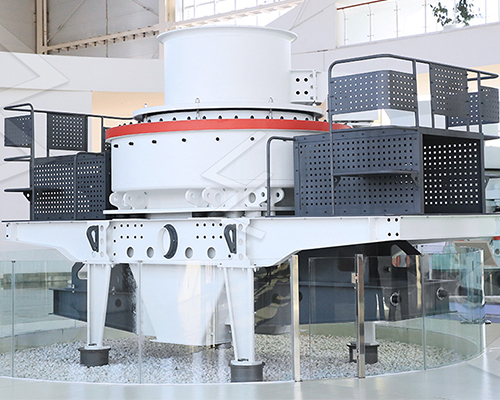

3. Sand Making – VSI6X1150 Impact Crusher

- Role: Produces high-quality 0-5mm sand with excellent gradation.

- Advantages:

- Deep rotor design for higher sand yield.

- Low iron contamination for premium concrete sand.

- Energy-saving motor reduces operating costs.

4. Screening & Conveying – S5X2460-3 Vibrating Screen & B6X Belt Conveyor

- Role: Classifies final aggregates into different sizes.

- Advantages:

- Multi-layer screening ensures precise separation.

- Dust-proof and noise-reducing design.

Technical Highlights

- Automatic Control System – Ensures smooth, stable production.

- Dust Suppression Technology – Eco-friendly and complies with Nepal’s environmental regulations.

- Easy Maintenance Design – Reduces downtime.

Project Results

Production Capacity: Exceeded target at 210-220 TPH.

Final Product Quality:

- Cubic-shaped aggregates for asphalt and concrete.

- Low powder content for high-grade sand.

- Operational Stability: 98% uptime even in tough conditions.

Customer Feedback

“Liming Heavy Industry’s crushing plant has greatly improved our production efficiency. The PE900x1200 jaw crusher and HPT300 cone crusher are extremely durable, and the sand from the VSI6X1150 meets international standards. Their team provided excellent after-sales support, making this a successful investment.

–Production Manager, Nepal Construction Co.“